Downtime is expensive — sometimes costing thousands of dollars every minute, a line sits idle. Traditional maintenance approaches often fall into one of two traps: reacting after something breaks or replacing parts on a set schedule whether they need it or not. Predictive maintenance takes a smarter route. By combining real-time data from your equipment with machine learning, it can spot problems before they cause an outage. With OPC Router, you can efficiently route PLC and sensor data into predictive models with minimal complexity.

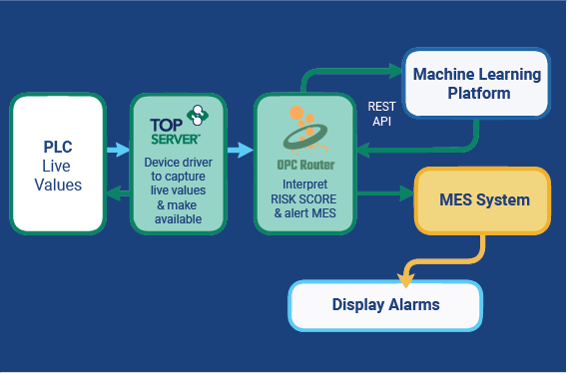

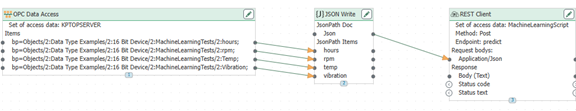

The diagram below shows how information flows from your shop floor into a machine learning model, and how the results come right back into your maintenance process.

What Predictive Maintenance Is and Why It Matters

Predictive maintenance (PdM) takes a proactive approach to keeping your equipment in top shape. Instead of waiting for something to break (reactive maintenance) or sticking to a rigid service calendar (preventive maintenance), PdM uses real-time data and analytics to spot when a machine is headed for trouble. That means you only perform maintenance when it’s needed — helping you avoid unexpected breakdowns and get more life out of your assets.

When done right, predictive maintenance can deliver big wins:

- Fewer surprises: Less unplanned downtime disrupting production.

- Lower costs: Spend less on emergency repairs and unnecessary part swaps.

- Longer equipment life: Address small issues before they cause major wear.

- Better safety: Catch problems early, before they become hazards.

From manufacturing to energy to logistics, companies are seeing serious payoffs by putting PdM into action.

The Role of OPC Router in Predictive Maintenance

OPC Router is like the central switchboard for your plant’s data. It bridges the gap between your operational technology (OT) systems and the analytics tools or enterprise applications that need that data. In a predictive maintenance setup, it plays a few key roles:

- Collects real-time data from your shop floor — pulling from PLCs, OPC UA/DA servers, and even MQTT brokers.

- Prepares and formats that data so it’s ready for your machine learning models to process.

- Uses smart triggers to send only the information that matters, right when it’s needed.

- Routes results back into your control systems, HMIs, MES, or alerting tools so your team can act on them immediately if a certain threshold is met.

Connecting OPC Router to Machine Learning Models

There are two main ways to connect OPC Router to your predictive maintenance models:

Cloud AI Services - Platforms like Azure Machine Learning, AWS SageMaker, and Google Vertex AI can host your predictive models in the cloud. With OPC Router’s REST Plug-in, you can send sensor data — packaged neatly in JSON — straight to these services. They’ll process it and send back predictions or risk scores, which OPC Router can use to kick off the right actions.

On-Premise AI Models - Some facilities prefer to keep all analytics in-house for security or speed. In that case, OPC Router can use its scripting or REST capabilities to call a local Python or R script running your model. This setup can return predictions in just milliseconds, without sending any data outside your network.

Example: Implementing a Predictive Maintenance Workflow

Let’s look at a common PdM use case: monitoring a packaging line motor for early signs of failure.

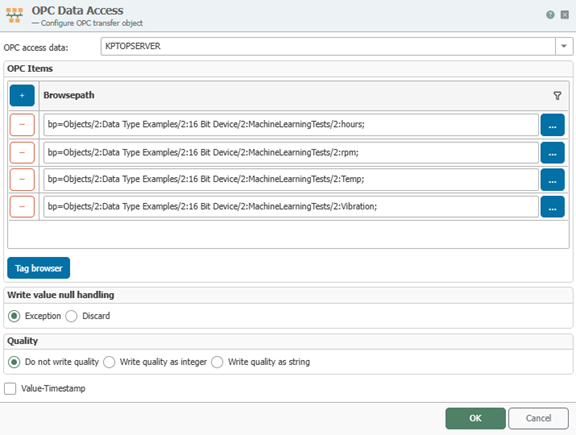

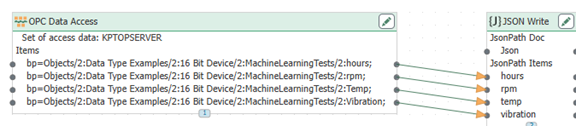

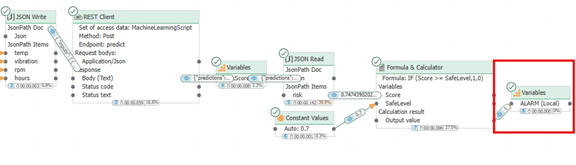

- OPC Router reads vibration, rpm, hours and temperature data from a PLC via OPC UA.

- The data is normalized and packaged into a JSON payload.

- Using the REST Plug-in, OPC Router sends the JSON payload to a Machine Learning endpoint.

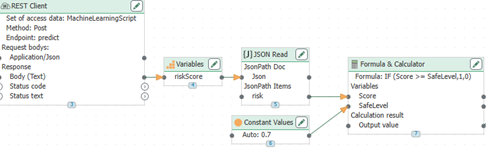

- The Machine Learning service processes the input and returns a ‘Risk Score’ (e.g., 0.0 to 1.0) indicating the probability of failure.

- OPC Router evaluates the score — if it exceeds a set threshold, it routes a ‘High Risk’ status to the MES for maintenance scheduling or publishes an MQTT message to alert the maintenance team. As you can see from the screenshot below, since the score was over our limit of .7, we raised the alarm variable to 1 to alert the team that action is needed.

Closing Insights: Minimize Downtime with Smart Maintenance

Predictive maintenance has a solid track record for cutting downtime, lowering costs, and helping equipment last longer. With OPC Router’s ability to connect and route data, it’s easy to link your shop floor systems to powerful machine learning models — whether they’re running in the cloud or right on-site.

Set up the right workflow, and you’ll be spotting potential problems before they cause trouble — and fixing them on your own terms.

Talk to our subject matter experts today to explore how OPC Router can support your predictive maintenance strategy.