Do you need to directly connect data points or variables in different equipment, processes, or software? This concept is commonly referred to as ‘point-to-point bridging,’ and the DataHub bridging capability allows multiple data sources to communicate with each other in real time.

In this second post of our “I Can Do That?” blog series, we’ll help users like you get the most out of your DataHub by understanding the bridging feature in detail and how this feature can often be combined with other features to accomplish some very powerful automation tasks.

Unlike other OPC-only bridging software, if the DataHub can communicate with a data source it can bridge the data, and setting up a point-to-point bridge in DataHub is the same regardless of the data source, which could include OPC DA, OPC UA, OPC A&E, DDE, and ODBC.

The DataHub also supports different APIs, such as .NET, C++, Java, and TCP, so any program on almost any operating system can send data to the DataHub, allowing it to be bridged with another data source.

To provide a better perspective on how bridging can be useful, let's look at some of the different use cases we’ve seen over the years.

Bridging Data Points between Different Hardware

The most straightforward use case is bridging two data points that come from different control systems, machine or processes. This has traditionally been between two OPC DA servers, but we’ve recently seen a shift where some of the OPC servers our clients use for device connectivity are OPC UA instead.

Since the DataHub supports both OPC DA and OPC UA, it can easily bridge between these two specifications in either direction – and the elegant part is that it’s all transparent to the user.

As discussed in a recent blog post, we can even bridge OPC A&E data to OPC DA or UA. That’s because the DataHub can convert the multiple properties of an OPC A&E data point into individual data points. Sometimes there’s a need to get OPC A&E data into an OPC system that doesn’t support OPC A&E; in this case, DataHub users have set up an OPC A&E to DA bridge that allows these systems to share useful information.

Bridging Excel / DDE to OPC Servers

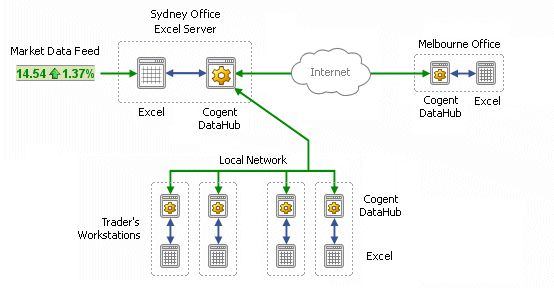

Many of our clients still use Excel for a variety of tasks – most often to record data manually – and some of this data must be shared with the control system. Since the DataHub supports DDE, it’s commonly used to bridge data from Excel into OPC servers. Although this application diagram is from a finance business who needed real time data, it’s quite applicable to industry because in industry we too have the same real time and high security needs as financial traders!

And, even though it’s becoming less common, we’ve even seen users with legacy DDE Servers communicating with their control hardware – another instance where DataHub facilitates bridging legacy DDE data with more modern OPC DA and UA systems.

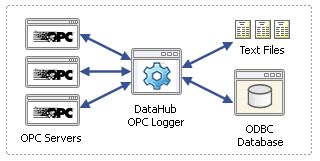

Bridging Databases to OPC Servers

Do you need to read data, such as recipes, out of a database and populate your PLC or HMI with that information? Many of our clients use the DataHub's ODBC interface to query a database based on information from the PLC, like batch IDs. Then DataHub bridges the results of that query to PLC registers via OPC DA or OPC UA so a process can start with the correct parameters for that batch.

And recipes are just an example – DataHub isn’t limited to reading recipe information. Other examples include databases for energy usage, shift schedules, environmental data, and MES systems.

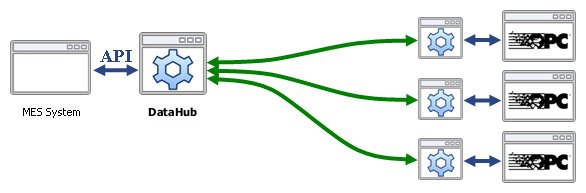

Bridging MES Systems to OPC DA and OPC UA

We’ve partnered with MES companies where DataHub has become their standard MES to OPC bridge to connect to the customer’s operations control layer. As it’s common for MES packages to support ODBC, that’s the typical method for connecting DataHub to the MES.

In situations where a particular MES can’t be accessed via ODBC, another method the MES vendor can use is writing a custom application that utilizes one of the DataHub APIs mentioned earlier (.NET, C++, Java, and TCP).

Then, that application pulls data from the MES system and, via the chosen API, bridges it to tags in the DataHub that are used in the HMI/SCADA. Similarly, sharing information from the HMI/SCADA with the MES can be accomplished through DataHub bridging as point-to-point bridges are configurable to be bi-directional or to operate in forward or reverse direction depending on the required behavior for the specific application.

With just a few clicks of the mouse, you can link OPC DA, UA and A&E servers with each other or bridge almost any other data sources such as databases, DDE servers, MES systems, using the DataHub. We’ve only covered the most common use cases, but if you find yourself needing to connect ABC to XYZ and everything in between, DataHub can bridge your data, too.

Above and beyond bridging data between different sources, other functionality includes sending email or SMS text reports or notifications, acting as a gateway solution between different types of OPC and other data sources, and more.

Don’t have DataHub yet? Click to Download Your Free Trial Software