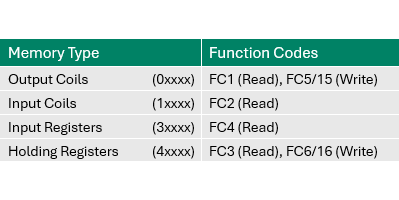

When working with Modbus communication, understanding the key concept of function codes is essential for ensuring efficient and accurate data exchange. Sometimes a device manual might only refer to the supported Modbus function codes and the range of offsets available for those function codes. A solid understanding of function codes is critical in achieving optimized performance and resolving potential communication issues.

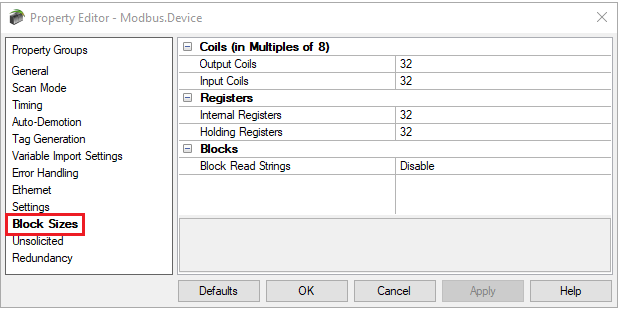

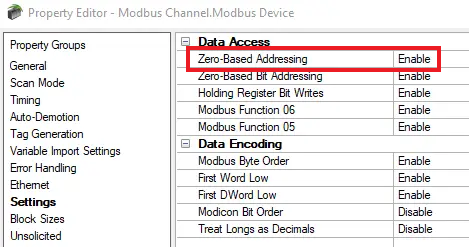

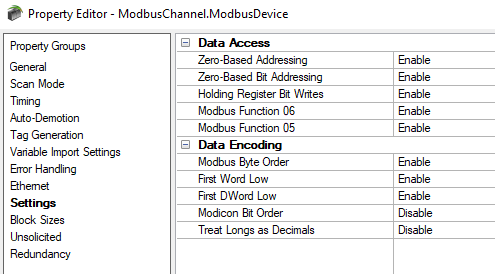

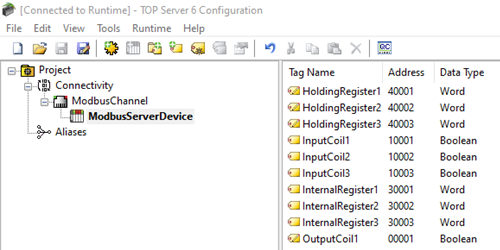

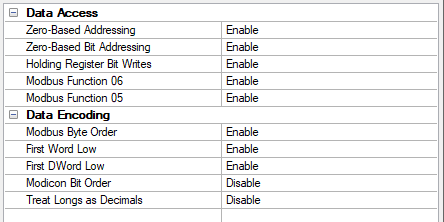

After reading this blog, you'll know how you can leverage TOP Server’s Modbus driver to automatically handle the appropriate function codes for your application – while also taking advantage of its flexibility and other advanced features – to enhance performance, ensure compatibility with your devices, and reduce troubleshooting time.