When people think of environmental sustainability, in general, they often do not think of the oil and gas industry. But the fact of the matter is that oil, natural gas and other hydrocarbons are a large part of our global energy supply and chemical production. There are many environmentally-focused regulations that these industries must meet. Even with these regulations, the industry has begun to exceed these expectations through technology such as carbon capture as a method of reducing one’s ecological footprint.

In this third installment of our Environmental Sustainability blog series, we are discussing oil and gas industry regulatory requirements and how industrial automation software solutions empower organizations in the industry with monitoring of critical data so they can act on potential issues before they become problems, and support their reporting to meet such requirements and also with monitoring such that those requirements can be more easily achieved.

Currently, energy production is the largest contributor to global greenhouse emissions. Governments are striving globally to create a more environmentally sustainable world, which includes reducing greenhouse emissions. For example, in the United States, the Executive Order on Climate-Related Financial Risk from 2021 was enacted in order to further the nation’s own industrial sustainability efforts. This Executive Order states that companies and industries who wish to work with the U.S. government must have the goal of net zero emissions by 2050. With that date quickly approaching, the use of technologies such as CO2 capture are needed more than ever to comply with the policy.

In our last post, we discussed the importance of environmental sustainability and how automation has the ability to empower efforts by companies to reach sustainability goals in a way that helps the environment while also saving money. As mentioned, CO2 capture is a great way to reduce carbon emissions and instead use it for other projects. Major companies like Oxy have been capturing CO2 for years (amongst other carbon footprint reduction initiatives) and have begun to utilize this technology to lower their emissions and instead use the captured carbon to help get more oil out of the ground more efficiently while also reducing the cost of CO2 as an input to the process. By capturing their own carbon emissions, Oxy has been able to become more sustainable both environmentally and monetarily while still being a very successful company.

As one of the largest CO2 users in the United States, Oxy's efforts result in substantial savings in the cost of CO2 that has to be purchased and in the elimination of used CO2 from the injections wells being released into the environment where it could inflict additional damage to our atmosphere.

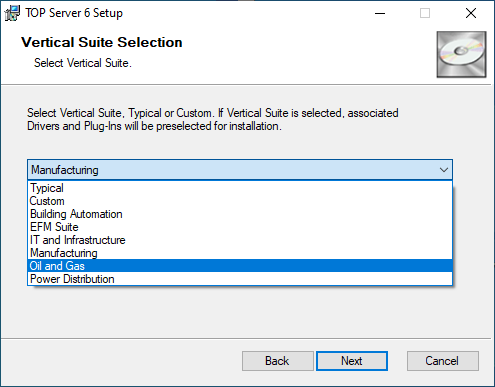

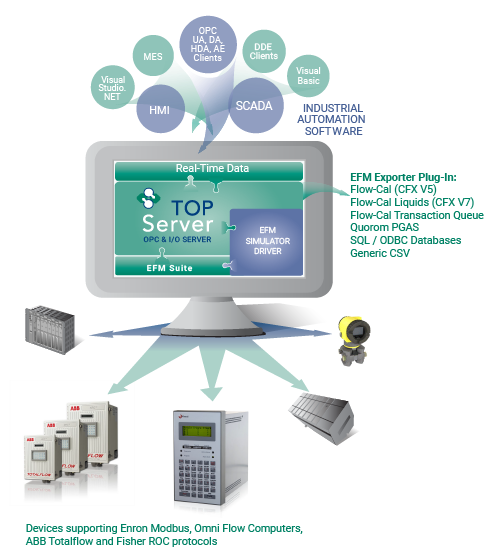

Also as previously mentioned in our last post, a significant measure towards reaching sustainability goals is to monitor energy output using modern technology systems. Industrial software solutions such as the TOP Server EFM Suite, Oil and Gas Suite, and Flow Software assist our users in the oil and gas industry with monitoring to address potential issues before they become problems, and in support of reporting for environmental standards.

Also as previously mentioned in our last post, a significant measure towards reaching sustainability goals is to monitor energy output using modern technology systems. Industrial software solutions such as the TOP Server EFM Suite, Oil and Gas Suite, and Flow Software assist our users in the oil and gas industry with monitoring to address potential issues before they become problems, and in support of reporting for environmental standards.

Monitoring using industrial automation software also provides critical data in support of streamlining production efficiency, CO2 monitoring, capture and reduction, but also aiding in the recognition and elimination of leaks, prevention of holding tank overflows and more to reduce negative environmental impacts. Cost savings are also achieved through the value of any lost output but also through prevention costly fines related to non-compliance with state and/or federal regulations. Between real-time data and Electronic Flow Measurement (EFM) historical data, issues can be fixed quickly in order to prevent such heavy fines.

In the United States, for example, despite variances in state-specific regulations for oil and gas transfer, several policies have been created at the federal level. For example:

- The Environmental Protection Agency (EPA) requires the report of all oil spills and the capture of all gases and fluids that are released in addition to their relationship to the production of oil and gas.

- The Department of Transportation's (DOT) Pipeline and Hazardous Materials Safety Administration regulates natural gas pipelines and underground natural gas storage in order to monitor and prevent spills that are damaging to communities and the environment.

- The Federal Energy Regulatory Commission (FERC) regulates the transportation of oil through interstate oil pipelines via several policies geared towards maintaining safe and efficient processes.

- The Bureau of Safety and Environmental Enforcement (BSEE) regulates all Outer Continental Shelf (OCS) oil and gas drilling and its production via several policies and regulations that set federal environmental standards.

Compliance with these regulations requires robust, reliable access to real-time and historical data that is also cleansed and contextualized, from all parts of operations for early detection of potential and actual issues but also completing reporting and accountability requirements.

How TOP Server Oil and Gas Solutions & Flow Software Empower Compliance & Sustainability Efforts

For oil and gas industry applications where real-time electronic meter, pump controller and other device data collection using multiple industry-standard protocols is required, the TOP Server Oil and Gas Suite provides users with a comprehensive collection of 13 of the most commonly used communications protocols for real-time data collection in the oil and gas industry. It's an economical choice in situations where an organization has a mixed variety of hardware from different vendors.

And for applications where flow computers and RTUs are being used for historical EFM (Electronic Flow Measurement) data collection, accounting, custody transfer, and analysis, the TOP Server EFM Suite helps. It supports collecting both EFM historical data and real-time data from a range of commonly used flow computer and RTU models and protocols and making that EFM historical data available for analysis in Flow-Cal, PGAS, and more. This functionality supports these users with meeting their custody transfer and accounting requirements, but also helps those users optimize their systems and, as required, use the data to complete reports for various regulatory agencies.

And for oil and gas industry users who are consuming both historical and real time data, the TOP Server Real-Time Scheduler Plug-in empowers the operator to optimize the collection of data across communication links of varying capacity, speed, and reliability, to insure robust data collection that avoids overlaps in the polling cyle, thus minimizing bottlenecks and ensuring efficient communications.

An equally important component in many parts of the facilities areas of oil and gas well sites, common PLCs such as Rockwell, Siemens, Schneider and others are used for monitoring and control of those processes. A major strength of TOP Server is the support for all major PLC brands and 100’s of other device types in the same OPC server as the EFM polling engine. By having a single integrated solution, operators can optimize communications in one place, their automation technicians and analysts have one product to learn and support, and a common management and troubleshooting interface.

Flow Software - From Data to Cleansed, Contextualized Information

TOP Server gets the data. But that is just the beginning. Although many of our users find it sufficient to act on the real-time data, and EFM Historical data used for custody transfer has to be shared in an encrypted, unalterable, secure method, which the EFM exporter provides, evolving requirements demand more.

What if the real-time data needs to be cleansed to remove invalid points, or aggregated into hourly, shiftly, daily, weekly, monthly measures that sometimes also use multiple real time points? Using Flow Software to leverage data from TOP Server and other industrial and business data stores, it's possible to gain even further insights from real-time and historical oil and gas data. Flow provides a programming free means to add contextualization across various data sources and apply KPI calculations to provide information users across all function levels in an oil and gas organization can take advantage of for more informed decisions. helps add that context from a variety of data sources including TOP Server, adding even further optimization for operational effectiveness across the organization. A business that is operating closer to peak effectiveness is more sustainable, efficient, and profitable.

Since 1996, we’ve helped users with wide and varied requirements, and we know you may have unique needs. This is especially true with the level of complexity commonly involved on many oil and gas projects. As such, we always encourage users to contact our team to discuss their project specifics so we can make proper recommendations to help them achieve their monitoring, analysis and reporting needs. And don't forget to subscribe to our blog for more posts on sustainability, best practices, tutorials and other industrial automation topics and resources.