Happy early Earth Day! And welcome back to our Environmental Sustainability series, where we explore the pivotal role of innovation in safeguarding our planet. In this third installment, our focus shifts to the chemical industry, where we will explore a compelling case study and uncover the strategies employed by one company to standardize and unify their operations with principles of sustainability.

Through this case study, we will witness firsthand how advancements in technology and strategic decision-making can yield substantial gains in energy efficiency. Join us as we investigate where the pursuit of efficiency intertwines with environmental stewardship.

Empowering Energy Efficiency through Data Aggregation

In an era defined by environmental consciousness and technological innovation, the quest for energy efficiency has become more than just a noble aspiration—it's a strategic imperative. As industries and individuals alike seek to minimize their carbon footprint and maximize resource utilization, the role of automation in driving energy efficiency has never been more crucial. In this automated world, our goal is to help shape a world where sustainability is not just a goal, but a reality we can all embrace.

The chemical industry user, that is the focus of our success story, offers a cloud hosted IoT solution that collects data from chemical plants and performs sophisticated calculations, simulations, and analytics on the incoming data. Running in Microsoft Azure, they are able to receive sensor data via a proprietary REST API endpoint.

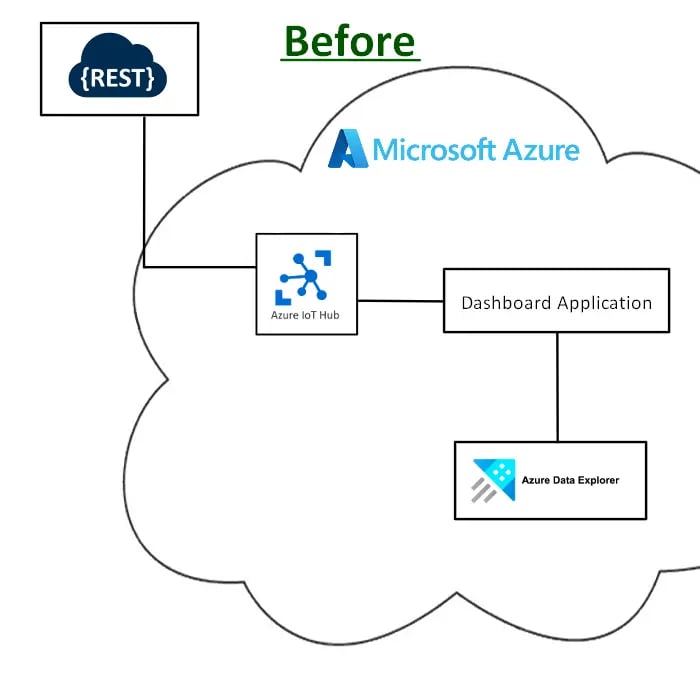

Users of this solution are able to leverage a dashboard application, which offers insight into plant operations, enabling them to improve production, reduce emissions, and optimize energy consumption. In its original state, here is a visual of the configuration:

While this solution clearly offers much benefit to its end users as-is, it didn't come without some challenges. There were other users that had a wide range of control systems that they wanted to unify into this centralized, cloud-based solution beyond the sensor data. There were some devices with embedded OPC UA Servers and other devices supporting Modbus TCP. This company had to satisfy this new requirement and embarked on a search for a secure, robust solution that was also scalable and sustainable for them to standardize on.

While this solution clearly offers much benefit to its end users as-is, it didn't come without some challenges. There were other users that had a wide range of control systems that they wanted to unify into this centralized, cloud-based solution beyond the sensor data. There were some devices with embedded OPC UA Servers and other devices supporting Modbus TCP. This company had to satisfy this new requirement and embarked on a search for a secure, robust solution that was also scalable and sustainable for them to standardize on.

The Cogent DataHub they worked with Software Toolbox to license and implement was already widely used by this organization for its well-known OPC Tunneling and OPC Gateway (DA to UA Conversion) functionality. Over the years, they had observed the DataHub's rapidly expanding functionality into MQTT, and decided it was time for them to take advantage of this for themselves.

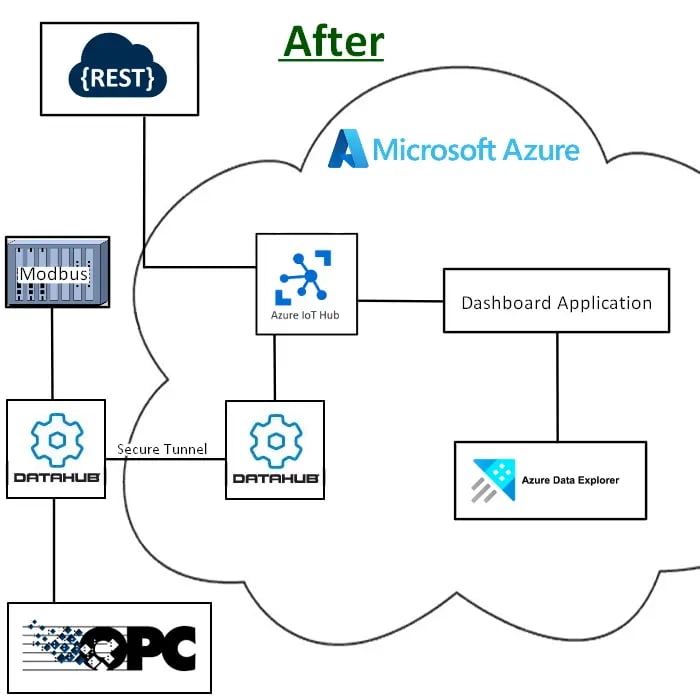

The Cogent DataHub would be able to pull in the data from their OPC data sources and straight from the Modbus TCP devices in the field and centralize the data into one DataHub instance. From there, the data could be securely tunneled to the Azure environment to a second DataHub instance, which would act as an MQTT Client and publish data to the Azure IoT Hub (MQTT Broker).

See here for our video tutorial on OPC to Azure IoT Hub with the Cogent DataHub.

The general nature of MQTT in itself was an added benefit. MQTT follows a report-by-exception message model that sends data only when there are changes to the state of the device or when data values change. This was developed around the idea of using MQTT as a very lightweight and efficient Publish/Subscribe communication protocol. Therefore, by transferring data from the DataHub MQTT Client to Azure IoT Hub, they would only be receiving the updates for the messages upon data change. The configuration evolved into this:

DataHub's depth of functionality also kept the door open for endless possibilities. In the long-term, this organization could also incorporate data from:

The ability to monitor and analyze energy consumption patterns within a single platform from all data sources allows the organization to gain invaluable insights into their operational efficiency and environmental impact. This can also enable systems to detect anomalies and flag potential issues early, allowing for proactive measures to prevent costly downtime and energy waste. This informed decision-making fosters accountability and encourages behavioral changes, motivating employees to adopt more energy-efficient practices and technologies.

Skkynet DataHub on Azure - The Cloud Companion to DataHub

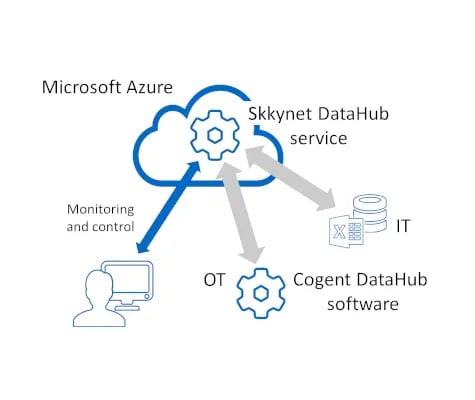

There is distinction that needs to be made between the two DataHubs in this configuration. The DataHub communicating directly to the Modbus and OPC data sources is a standard on-premise DataHub instance; however, the data is then tunneled to a Skkynet DataHub on Azure.

Available in the Azure Marketplace, the Skkynet DataHub is a Microsoft Azure Managed Application that is optimized to securely receive data using all of DataHub's secure and robust tunneling capabilities, allowing for seamless integration with your on-premise DataHub instances for IT/OT integration, centralized historians, cloud historian and SCADA integration, analytics, AI and more!

Because licensing of the Azure service is consistent with other native Azure apps, it can be more cost effective than taking a full DataHub on-premise license and paying for an Azure hosted full virtual machine, as you only pay for resources consumed.

Because licensing of the Azure service is consistent with other native Azure apps, it can be more cost effective than taking a full DataHub on-premise license and paying for an Azure hosted full virtual machine, as you only pay for resources consumed.

The Skkynet DataHub on Azure is configured using the same remote configuration interface that used for a standard on-premise DataHub. The cloud service usage can also be monitored via the SkkyHub web portal. Cloud storage also further allows users to dynamically allocate resources based on demand, optimizing server usage, and reducing the need for idle servers, hence saving precious energy. This is also example of last week’s post where we discussed the energy saving benefits of cloud applications.

Conclusion

In the end, this user benefitted from DataHub because it further enabled their IoT solution and allowed for expansion across many different systems to broaden their efforts in improving production, reducing emissions, and optimizing energy consumption.

Utilizing cloud-based software to monitor and manage energy usage allowed this organization to achieve tangible results in their efforts towards sustainability. Energy tracking enables the identification of areas where energy is being wasted within daily, monthly, and annual processes. By monitoring energy usage in real-time and analyzing historical data, inefficiencies can be pinpointed and rectified, leading to significant energy savings.

If you think or want to further discuss how DataHub and other solutions from Software Toolbox can help you maximize your data and address your automation integration challenges, please contact our team today!

As always, feel free to contact our support team with any questions and remember to subscribe to our blog for more quick and easy DataHub tutorials and tips. And, if you haven't already, make sure to download the latest free trial version of DataHub to get started connecting your systems and devices.