Our  is designed to help professionals that are new to the industrial automation space whether at the start of their careers, or moving into the operations technology (OT) world from an IT or other background.

is designed to help professionals that are new to the industrial automation space whether at the start of their careers, or moving into the operations technology (OT) world from an IT or other background.

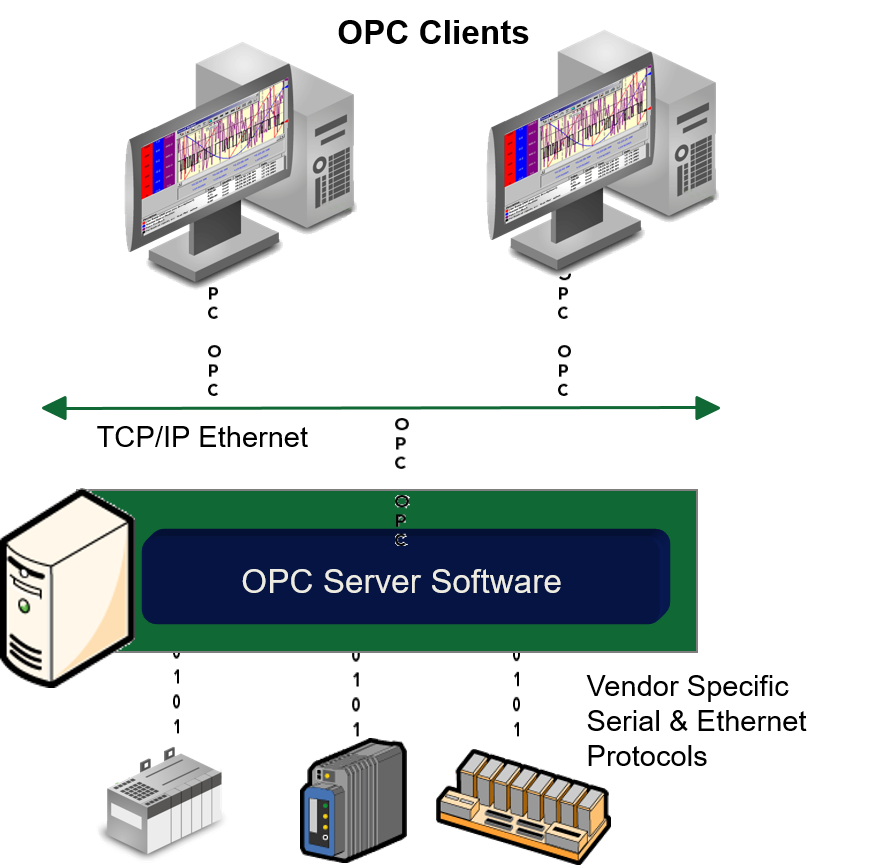

One of the common challenges in Industrial Integration is communications between different brands or manufacturers’ control devices (PLC, DCS, Drives, RTUs, smart sensors). While most control devices have methods of communication, and some industry standards have helped, they don’t all communicate using the same methods or protocols, and even if they both have the same serial or Ethernet wiring the difference in communication protocols prevents them from passing information. It’s the same problem you have if someone calls you on the phone, but doesn’t speak the same language.

While, as humans, we may be able to overcome a difference in dialect, machine communication has to be precise and exact. Small differences in addressing or data formatting can be enough variation to create communications failure. So how do people overcome this challenge?