If you're interested in LGH history data and are reading this, you likely have your own use case for working with InTouch LGH history files. Given that LGH files are a classic method for InTouch users to log historical process data, the use cases for LGH history data are similar to any other use cases for historical data. Trending and predictive analytics can be key methods that utilize historical data for identifying process issues and resolving them in an efficient and cost-effective manner.

This blog post covers a specific use case involving an engineering research student working on a condition and performance monitoring system for subsea hydraulic systems targeted at identifying the health of the system and supporting predictive maintenance.

Predictive analytics and the efficiencies it provides through minimizing downtime and optimizing processes make the collection and utilization of historical process data more important than ever in today's industrial enterprises. In businesses where even a minute of downtime can mean thousands or even millions of dollars of lost productivity, effective predictive maintenance methods are worth their weight in gold and achieve a rapid return on investment, in most cases.

Recently, a Masters program engineer in Subsea Engineering at an esteemed public research university in Western Europe was focused on his thesis project. That project had the goal of establishing how the integrity of a subsea hydraulic system (common in offshore oil & gas) can be proactively maintained by consuming all available historical logs, data and information, and using that raw process data to model actionable condition statuses for the overall health of that system.

Recently, a Masters program engineer in Subsea Engineering at an esteemed public research university in Western Europe was focused on his thesis project. That project had the goal of establishing how the integrity of a subsea hydraulic system (common in offshore oil & gas) can be proactively maintained by consuming all available historical logs, data and information, and using that raw process data to model actionable condition statuses for the overall health of that system.

The HMI for the subsea system was developed with Wonderware InTouch which, in lieu of a formal historian on this particular system, produces LGH history logs (.lgh format). Since the engineer's project involves analysis and trending of only a certain subset of tags specific to the hydraulic system, the engineer needed a way to be able to read and interpret the historical LGH file.

Options for Accessing LGH File Data

As anyone who is familiar with LGH history data is aware, there are several options available for accessing and parsing the history data in an LGH file.

- Wonderware Historian supports direct import of LGH files. However, for smaller systems (especially those on a budget), this option can be both restrictive and cost prohibitive.

- The HistData utility is a traditional method for accessing LGH file data. However, it requires a fair amount of scripting to get the desired results, it doesn't run as a service and it has to explicitly be running for the configured scripts to actually execute. Additionally, it's limited to a maximum retrieval of 2000 rows at a time.

- In doing research online, this engineer found a third potential option - the LGH File Inspector, which enables rapid and easy access to local historical data logged by Wonderware InTouch to LGH files.

How Did LGH File Inspector Help with Predictive Analytics?

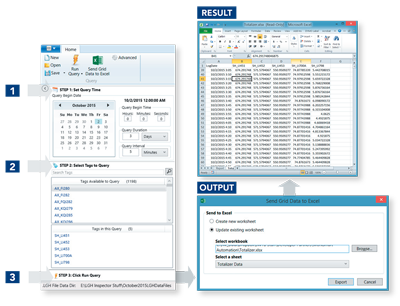

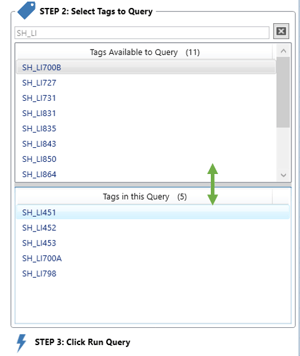

LGH File Inspector provided the engineering major with the flexibility he needed to define tags specific to the hydraulic data his project required from among the huge number of tags available in the LGH history. On top of that, the multiple option filters available in LGH File Inspector allowed the engineer to fine tune the target tag set by a number of variables including date, start scan rate, span, etc.

LGH File Inspector provided the engineering major with the flexibility he needed to define tags specific to the hydraulic data his project required from among the huge number of tags available in the LGH history. On top of that, the multiple option filters available in LGH File Inspector allowed the engineer to fine tune the target tag set by a number of variables including date, start scan rate, span, etc.

After the extraction of the history data for the defined set of tags, the raw hydraulic data could then simply be plotted and trended in Microsoft Excel. Using those trends, it then became possible to reveal any previously unseen patterns of degradation.

Once identified, a comprehensive historical view of the integrity of the subsea hydraulic system made it possible to anticipate when a potential equipment failure could be expected based on previous occurrences.

With that predictive framework in place, it now becomes possible to schedule preventive maintenance on any equipment forecast to have issues based on that made before those issues happen. As anyone in a process industry can confirm, planned maintenance downtime is far less volatile and cost-prohibitive than unexpected downtime.

LGH File Inspector helped this Master's program engineer easily solve the problem of extracting a specific subset of historical process data from LGH history files and prove the value of condition and performance monitoring towards predictive maintenance in subsea process applications.

If you're nodding your head and can appreciate the value such an easy-to-use, flexible solution to expose your historical process data that is stored in LGH history files, click below to get started with your own LGH files using the free trial of LGH File Inspector.