When you live in a remote region that is one of the most arid places on earth, you import your raw materials, and you’re making millions of hectoliters of beer a year, you have to make the most of all the resources you have and leverage what is in abundance in your location. Namibia Breweries Ltd. (NBL) has a long history of success in a tough environment at their Windhoek site. They have received numerous awards for their innovative approaches to meeting their information system needs.

In this blog post, we’ll share their look into how they use off-the-shelf software and their teams' intellectual know-how and creativity to empower their manufacturing success. If you read the stories in Automation World or Pro Food World you learned about how Andre Engelbrecht, manager of industrial control systems at NBL, and his teammates Annemarie Kruger, Rolando du Pisani and others unlocked data sources and built a digital smart manufacturing platform across the entire facility. In this article, we’re going to share the rest of the story of NBL’s integration points, problems solved, and how they leveraged Software Toolbox’s full value proposition as part of their team effort.

In this blog post, we’ll share their look into how they use off-the-shelf software and their teams' intellectual know-how and creativity to empower their manufacturing success. If you read the stories in Automation World or Pro Food World you learned about how Andre Engelbrecht, manager of industrial control systems at NBL, and his teammates Annemarie Kruger, Rolando du Pisani and others unlocked data sources and built a digital smart manufacturing platform across the entire facility. In this article, we’re going to share the rest of the story of NBL’s integration points, problems solved, and how they leveraged Software Toolbox’s full value proposition as part of their team effort.

Process Relationships are Critical

Like most manufacturing processes I’ve learned about, there’s more than most consumers realize that goes into making things. What readers may not realize about a large scale brewery is how interdependent all the processes are. When you are seeking to run a green or sustainable facility in a tough environment those dependencies matter even more. Take for example CO2. Fermentation produces it, and packaging beer needs it. You’d think with a “perfect” nice balance, you never have to source CO2. But if you have too much CO2, you can sell that to compressed gasses companies. But if you have to stop brewing, and you have beer ready to package, you need to have enough CO2 around to package that beer before it goes bad, otherwise you have to go buy CO2 externally. So you better have good monitoring for all aspects that help you insure you don’t run out of CO2 while also making some money selling your excess.

We’ll share some more examples later but let’s now look more at NBLs specific integration points and problems solved. One thing that NBL has plenty of is sunshine. To tap that resource, they have a 1 MW solar plant on the roof of their 140,000 m2 facility. That solar plant has 4,000 panels and 66 inverters. To monitor power consumption throughout the plant there are 50 digital power meters. Ironically, there is a coal-fired power generation station nearby, whose stack emissions can coat the solar panels and reduce their effectiveness. Add to that the regular dust storms and keeping that solar power plant optimal can be challenging.

We’ll share some more examples later but let’s now look more at NBLs specific integration points and problems solved. One thing that NBL has plenty of is sunshine. To tap that resource, they have a 1 MW solar plant on the roof of their 140,000 m2 facility. That solar plant has 4,000 panels and 66 inverters. To monitor power consumption throughout the plant there are 50 digital power meters. Ironically, there is a coal-fired power generation station nearby, whose stack emissions can coat the solar panels and reduce their effectiveness. Add to that the regular dust storms and keeping that solar power plant optimal can be challenging.

A starting point - Open Software & Power Management

To resolve this problem, NBL has implemented a power management system built on Wonderware Historian,  , and

, and  . Using this system through a browser interface, they monitor the output and efficiency of the inverters and when that decreases, they decreases, they know it’s time to send someone to the roof to clean the solar panels that feed that inverter.

. Using this system through a browser interface, they monitor the output and efficiency of the inverters and when that decreases, they decreases, they know it’s time to send someone to the roof to clean the solar panels that feed that inverter.

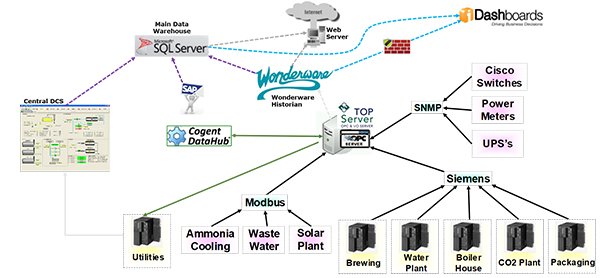

The TOP server Modbus Suite drivers gather the data from the inverters and then delivers it to the Wonderware historian, but it also pushes relevant information into a Siemens PLC using the Cogent Datahub’s OPC bridging capability, and the TOP Server Siemens suite drivers. In the end, their BrewMaxx DCS/MES system then gets its information from those Siemens S7 PLCs.

The TOP Server Modbus suite drivers also gather data from the diesel generators that NBL employs to insure their facility has electricity even when their local power grid has a problem, or the solar farm is outputting less than normal on a rare cloudy day. Lastly, there are a number of water wells on the plant site and nearby which must be monitored to insure this highly precious resource is not wasted. Those too are integrated using the TOP Server Modbus Suite drivers.

Completing the power and infrastructure monitoring, NBL uses the TOP Server SNMP suite to gather operating data from the plant Power Meters, UPS battery backups, and Cisco Network switches. “The beauty of this solution is that no matter the protocol, once we have that data in TOP Server, we can historize that data in Wonderware Historian, bridge required data into the S7 PLCs, but also over to the Central DCS via Cogent Datahub’s SQL integration capabilities,” says Engelbrecht. “The open-standards based approaches mean the only limits we have are our imaginations and time to implement all our ideas”, adds Engelbrecht.

The NBL integration points didn’t end there. The core of all their brewing processes are managed by Siemens S7 PLCs. From the water plant to boilers, brewing, CO2 plant to packaging, it’s controlled by those Siemens PLCs. The same TOP Server Siemens drivers gather that data, supply it to the Historian, and on to the BrewMaxx central DCS. All told, between the TOP Server and Cogent Datahub software, they are responsible for integrating 100’s of PLCs and systems.

Integrated Information Delivers Results

“Having all this information available in one place has empowered our team to address some interesting challenges in our highly green process,” says Engelbrecht. When I visited the NBL facility recently, Andre and his team took me on a tour and shared some fascinating stories. Throughout all the stories, Andre would point out how the Software Toolbox products made available the information that resulted in the story. For our team, the satisfaction of knowing they make a difference for the client energizes them to do what they do so well.

Can you remove invasive species to make beer?

Sounds odd, but every ecosystem in the world has some form of invasive plant or animal species. In Namibia, there are certain trees that were introduced from abroad and manage to grow vigorously in the arid climate but, in the process, are starving other necessary native species. NBL is doing their part to help this through their biomass boiler shown here. They purchase wood from these invasive trees as farmers remove them, grind it, and use it for fuel for their superheated (155 C) water system. As you know, brewing uses a lot of hot water and steam, so NBL’s needs help their nation remove an invasive species.

Sounds odd, but every ecosystem in the world has some form of invasive plant or animal species. In Namibia, there are certain trees that were introduced from abroad and manage to grow vigorously in the arid climate but, in the process, are starving other necessary native species. NBL is doing their part to help this through their biomass boiler shown here. They purchase wood from these invasive trees as farmers remove them, grind it, and use it for fuel for their superheated (155 C) water system. As you know, brewing uses a lot of hot water and steam, so NBL’s needs help their nation remove an invasive species.

In showing off this system, Andre mentioned that they were having problems with the self-cleaning systems in the boiler tubes. Using data that TOP Server gathered, they were able to detect that during the cleaning cycle, when solenoids were supposed to open, resulting in a pressure change in the tubes, only 1 in 20 were reaching the proper pressure. Using that data, they were able to work with the boiler OEM to rectify the issues and help their biomass boiler reach peak efficiency.

Brew some beer, feed dairy cattle?

Brew some beer, feed dairy cattle?

Another outstanding example of green, sustainable manufacturing is NBL’s relationship with a local dairy producer. NBL sells the spent wort from their brewing to those farmers. They store the materials in silos and, periodically, the dairy comes and picks up the product. Historically, the dairy had to speak with someone at the brewery before they sent a truck over for a pickup. But sometimes that didn’t happen, or the information was wrong, and the dairy truck would show up only to find out there wasn’t a full truckload available. Time wasted, fuel wasted, pollution generated. Annemarie Kruger, one of Andre’s team, has since built a web-based system that leverages data from TOP Server to enable the dairy to securely check on the tank levels on their own before they come over, thus eliminating wasted trips and the resulting environmental impact.

In the end, it's about the beer

One area that NBL is also very proud of is their Reinheitsgebot or "German Beer Purity Law" designation. Any beer connoisseur is likely familiar with this law.

One area that NBL is also very proud of is their Reinheitsgebot or "German Beer Purity Law" designation. Any beer connoisseur is likely familiar with this law.

For 500 years, the Reinheitsgebot rules regulate the ingredients and cleanliness of the process. NBL must undergo regular inspections in order to maintain the Reinheitsgebot designation for its products.

No visit to any of our brewing customers is complete without a visit to the plant pub, as shown here, with Annemarie Kruger and Andre Engelbrecht on my recent visit. Our mascot “Pierre the Duck” also came along too.

And to be sure you have a feel for just how arid it is in Namibia, here’s a view from their famous sand dunes where, of course, we had to enjoy some Windhoek Draught beers! Thank you to Andre & Annemarie for being wonderful hosts and keep up the great job at NBL!

Learn more about NBL's integration of their Brewmaxx DCS with SAP using DataHub in the sequel to this blog post.

References

The links below provide more information about the Software Toolbox products used in the NBL applications:

Don't forget to subscribe to our blog for more stories, use cases and how-tos like these!