When you live in a remote region that is one of the most arid places on earth, you import your raw materials, and you’re making millions of hectoliters of beer a year, you have to make the most of all the resources you have and leverage what is in abundance in your location. Namibia Breweries Ltd. (NBL) has a long history of success in a tough environment at their Windhoek site. They have received numerous awards for their innovative approaches to meeting their information system needs.

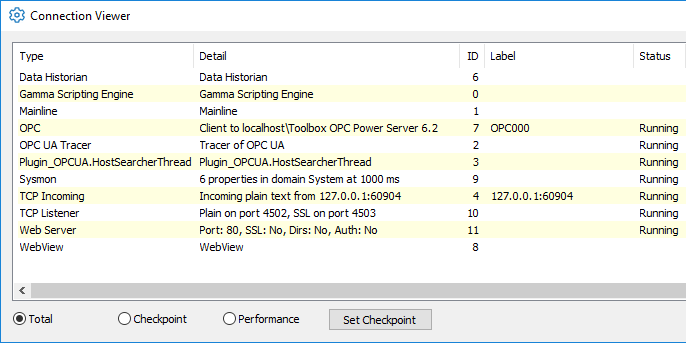

In this blog post, we’ll share their look into how they use off-the-shelf software and their teams' intellectual know-how and creativity to empower their manufacturing success. If you read the stories in Automation World or Pro Food World you learned about how Andre Engelbrecht, manager of industrial control systems at NBL, and his teammates Annemarie Kruger, Rolando du Pisani and others unlocked data sources and built a digital smart manufacturing platform across the entire facility. In this article, we’re going to share the rest of the story of NBL’s integration points, problems solved, and how they leveraged Software Toolbox’s full value proposition as part of their team effort.