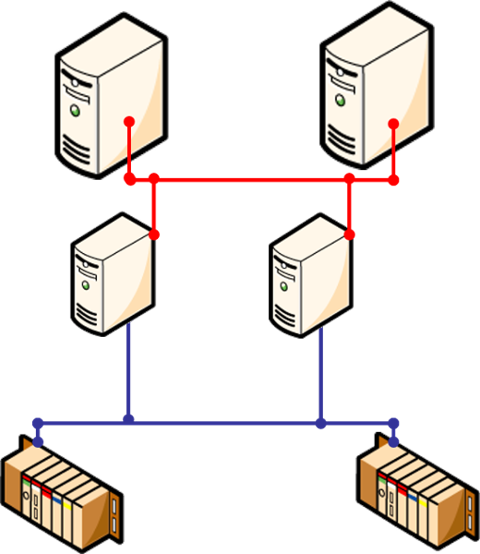

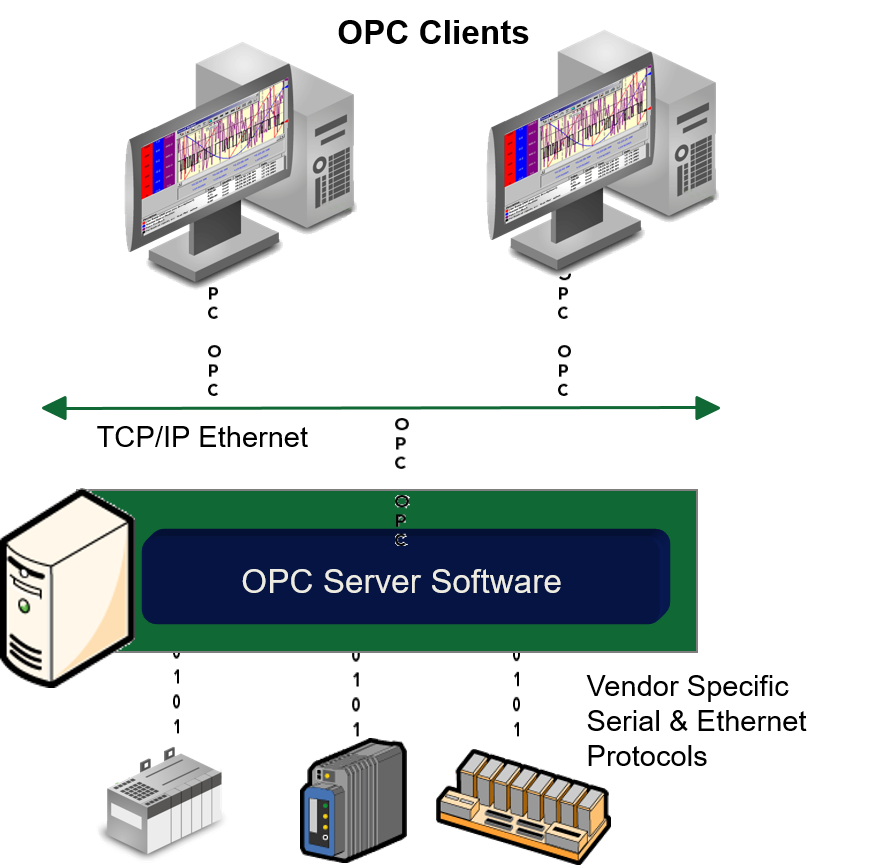

The heart of any control system is the computers and servers that run your automation software. For example, when PLCs talk to AC drives over Ethernet, the drives will shut down if they lose communications for more than a second, sometimes even milliseconds. Drives shutdown = Line shutdown = Plant shutdown. What IT calls a blip for plant operations can mean downtime, scrapped product and even your company’s reputation due to missed delivery deadlines.

Traditionally, server maintenance and upkeep is the role of IT. However, when these systems go down, it affects operations (OT) with different pains than IT sees on the business side. IT has systems to monitor their own assets, on the standards they need for the business, but they need the OT side to expand monitoring of their own systems and self-reliance in order for OT to meet operational needs, while bringing in IT as a resource.

This blog post will discuss how to get information about health of servers and PCs that runs the automation software OT users need without having to rely solely on IT.