As Cogent DataHub continues to evolve, version 11.04 delivers a focused set of enhancements that build on the powerful foundation introduced with the V11 major release. This update prioritizes performance, reliability, and expanded cloud readiness, ensuring DataHub remains a trusted platform for moving industrial data efficiently and securely.

Software Toolbox Technical Blog

Recent Posts

NEW Release - DataHub V11.0.4

7 min read

By Jessica Dillon on Jan 22, 2026 4:00:00 PM

Getting Started with OmniServer and Barcode Scanners

3 min read

By Jessica Dillon on Oct 16, 2025 2:00:00 PM

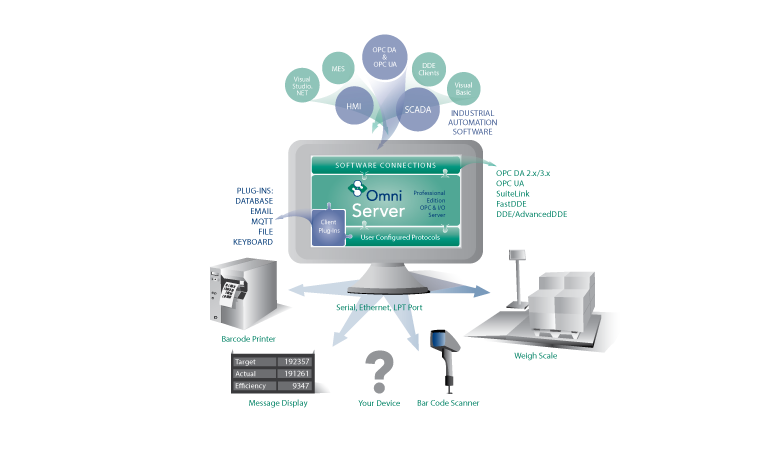

OmniServer is a universal data acquisition application designed to bi-directionally exchange data with a wide range of Ethernet, serial, or USB devices that use “non-standard protocols” such as weigh scales, barcode readers, lab instruments, inspection machines, printers, and more.

The wide range of connectivity options enable OmniServer to send that data to HMI, SCADA, MES, or Historian systems using standard interfaces like OPC DA, OPC UA, and AVEVA SuiteLink. It also has an optional MQTT Client Plug-In that allows users to publish data to MQTT Brokers.

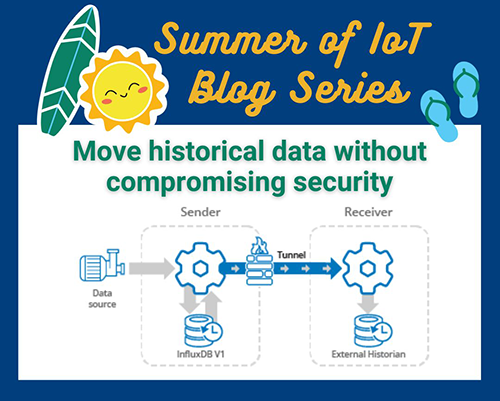

Protecting Historical Data Integrity Using Store & Forward

8 min read

By Jessica Dillon on Jul 31, 2025 2:00:00 PM

Welcome back to the Summer of IoT Blog Series. In this blog we’ll explore how Cogent DataHub’s External Historian and built-in Store and Forward features ensure efficient data flow without risking network security at the plant or enterprise level.

As organizations work toward Industry 4.0 and digital transformation, ensuring secure and reliable OT/IT convergence is essential for breaking down data silos and creating cohesion between your business systems. IoT devices provide real-time data and connectivity to transform traditional industrial operations. Complementing this, historians serve as centralized data repositories that store and organize time-series data from IoT devices and other sources. Together, the data from both fuels advanced analytics, automation, and smart decision-making across the enterprise.

Success Story: How a UK Retailer Improved Logistics with Real-Time Data

4 min read

By Jessica Dillon on May 22, 2025 2:00:00 PM

A leading UK retailer, serving millions of customers through an extensive store network, set out to modernize aging infrastructure in its high-throughput distribution centers. Burdened by legacy equipment and unsupported software systems, the organization needed a reliable way to bridge communication gaps without replacing critical machinery.

By working with a UK-based system integrator who leveraged OmniServer and OPC Data Logger software applications from Software Toolbox, the retailer achieved real-time visibility, accurate data collection, and the ability to respond quickly to underperformance. The result: improved fulfillment quality, reduced freight waste, and smarter use of transport resources.

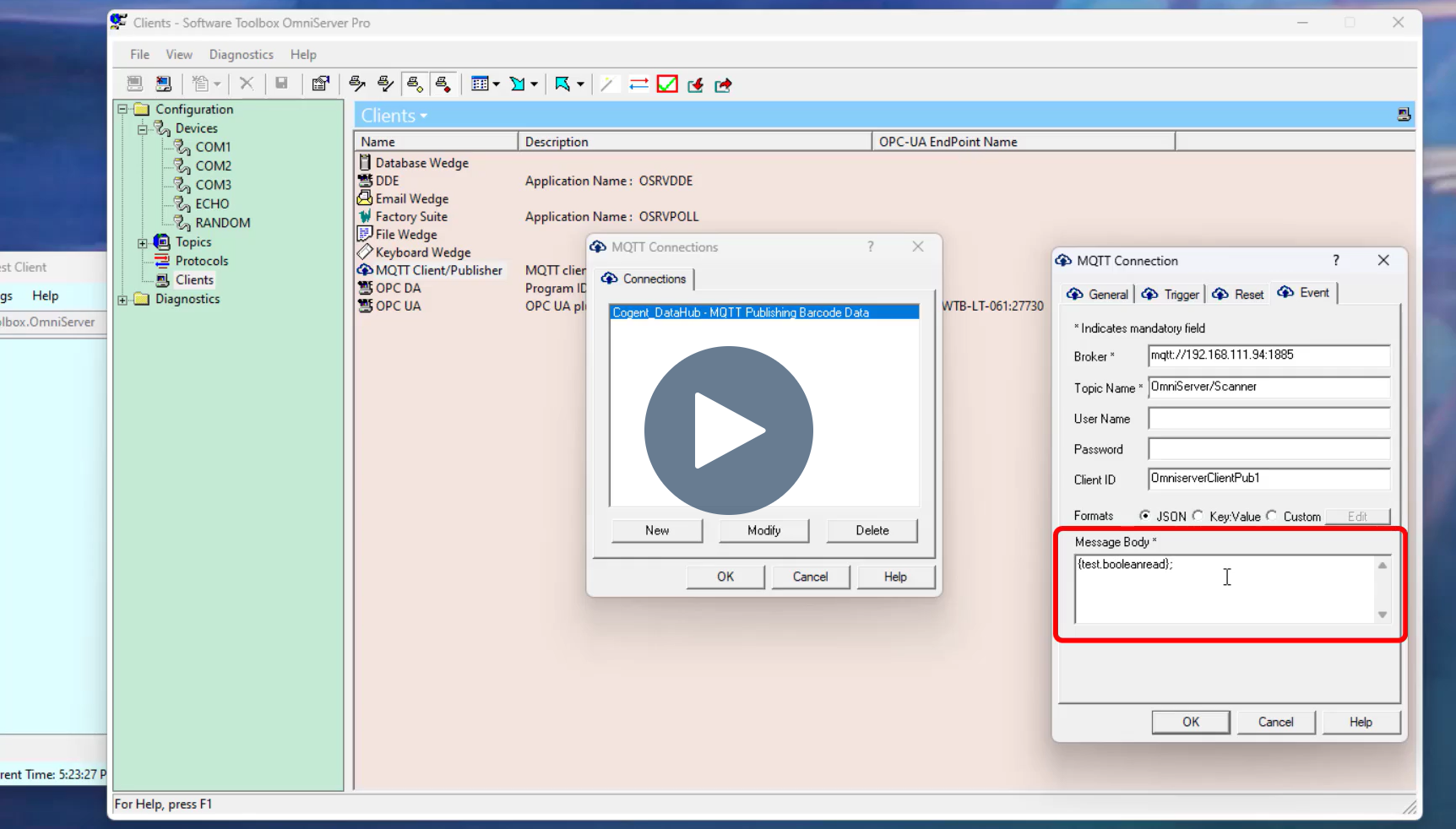

Video Tutorial: Publishing with OmniServer’s New MQTT Client Plug-In

2 min read

By Jessica Dillon on Sep 5, 2024 2:00:00 PM

OmniServer is a universal data acquisition software application designed to bi-directionally retrieve information from a wide range of Ethernet, serial, or USB devices that use 'non-standard' protocols to communicate, such as weigh scales, barcode readers, lab instruments, inspection machines, printers, & more. This data is then typically delivered by OmniServer to HMI, SCADA, MES, & Historian systems using standard protocols like OPC DA, OPC UA, & AVEVA Suitelink.

Streamline Your IoT Operations with the New OmniServer MQTT Plug-In

5 min read

By Jessica Dillon on Jul 11, 2024 2:00:00 PM

Welcome back to our Summer of IoT blog series! This week, we are excited to announce the release of OmniServer Version 3.4.0.1 which in the professional edition, now includes MQTT client capability, which enables publishing data to MQTT Brokers such as the Cogent DataHub Smart Broker, HiveMQ, Mosquitto, and others.

Did You Know? How to Use Character Translations in OmniServer

4 min read

By Jessica Dillon on Mar 28, 2024 2:00:00 PM

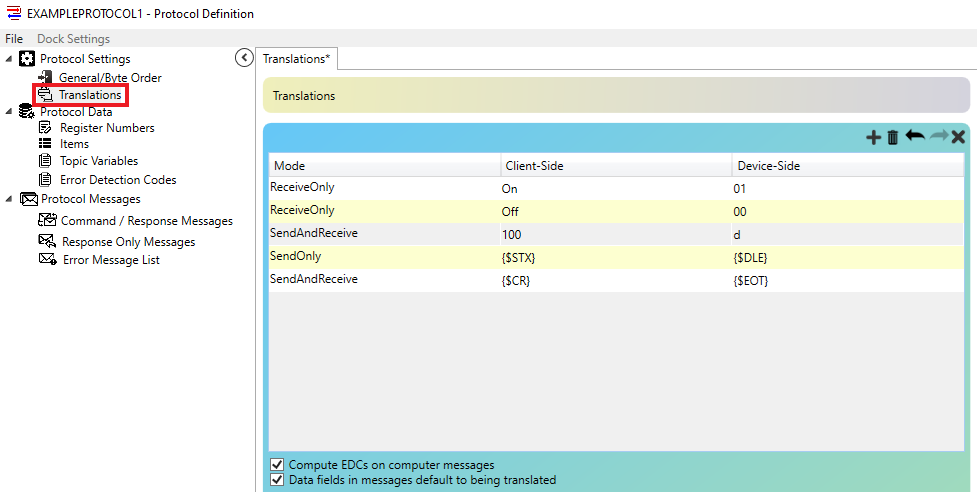

Those of you who are aware of OmniServer will already know that it is primarily used to retrieve information from devices that use 'non-standard' protocols to communicate, such as weigh scales, barcode readers, and printers. An HMI, SCADA, MES, Historian, database, and more, could then read that data from OmniServer, making it a powerful, universal, data acquisition tool.

Some of these 'non-standard' device protocols require what we call "special handling". For most protocols, if you've used OmniServer, data that is sent or received is "what you see is what you get" type data. An ASCII "A" is transmitted or received and interpreted as an ASCII "A". But what if your device is expecting something else as part of its special handling in its communication protocol? Or what if you wanted to interpret the data differently from the device to meet new business standards or existing requirements?

OmniServer is capable of handling advanced protocols where the devices send special characters/bytes that need to be handled in a specific way. In this blog, we will explain how to use a feature called "translations" in OmniServer with certain protocols that require special handling.

Automating Data Entry from Test Stand & QC Devices as Keyboard Input

9 min read

By Jessica Dillon on Feb 1, 2024 2:00:00 PM

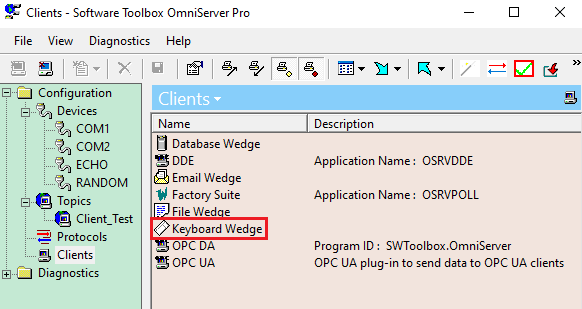

Unlike off-the-shelf OPC servers and drivers that talk to specific devices or protocols and no others, OmniServer can be configured to talk to virtually any device or combination of serial, USB, or Ethernet connected devices with some outliers based on the complexity of the protocol. OmniServer helps you bring data that would otherwise be inaccessible into your process and business systems, helping you make more effective decisions. In our experience there are still many software applications that do not have open interfaces such as OPC for data input. This is particularly common in quality control and test stand applications. Operators use a digital device to capture a measurement, and then have to type that into their test stand or QC software. This slows testing rates and can be error prone. There is a better way.

About this Blog

We're engineers like you, so this blog focuses on "How to" appnotes, videos, tech team tips, product update announcements, user case studies, and other technical updates. Subscribe to updates below. Your feedback and questions on posts are always welcomed.

Subscribe to our Blog

Recent Posts

Posts by Topic

- Device Connectivity (205)

- Wonderware (178)

- OPC UA (121)

- Cogent DataHub (111)

- TOP Server (108)

- OPC (103)

- Technical Support (99)

- OmniServer (73)

- Video Tutorials (69)

- OPC Router (52)

- OPC DA (42)

- Protocols (40)

- AVEVA (37)

- Automation 101 (28)

- Security (26)

- MQTT & IoT (24)

- OmniServer Did You Know (24)

- Data Tunneling (23)

- Connectivity (22)

- OPC Data Client (22)

- Development Tools (19)

- IT/OT (19)

- DCOM (17)

- LGH (14)

- OPC Tunnel (13)

- Alarms & Notifications (12)

- Database (12)

- Earth Day (12)

- Summer of IoT (12)

- Exploring OPC UA (11)

- OPC Gateway (11)

- REST & Web Services (11)

- Case Studies (10)

- Dream Report (10)

- EFM (10)

- Oil & Gas (10)

- Reporting (10)

- CSV (9)

- Database & Historian (9)

- OPC Integration (9)

- Flow (8)

- OPC Server (8)

- Redundancy (8)

- Sustainability (8)

- AVEVA OPC UA Client (7)

- Modbus (7)

- OPC Router Basic Training (7)

- SuiteLink (7)

- DataHub Training (6)

- ODBC (6)

- OPC Alarms and Events (6)

- OPC Conversion (6)

- OPC Data Logger (6)

- ProtocolDesign (6)

- xml (6)

- Data Bridging (5)

- Data Logging (5)

- Data Storage Deep Dive (5)

- Business Intelligence (4)

- Data Integration (4)

- InTouch (4)

- Industrial Decisions (4)

- Industry 4.0 (4)

- OPC Bridge (4)

- OPC Redundancy (4)

- OPC Toolkit Benefits (4)

- OmniServer User Stories (4)

- SLIK-DA (4)

- SQL (4)

- Collaboration (3)

- Error Detection (3)

- IT & Infrastructure (3)

- OPC Server Remote Config (3)

- Wedges (3)

- Windows (3)

- ControlLogix (2)

- Excel (2)

- Ignition (2)

- KEPServerEX (2)

- Kepware Edge (2)

- OPC Wizard (2)

- OSIsoft (2)

- Omron (2)

- PGAS (2)

- Predictive Maintenance (2)

- Process Alert (2)

- Scripting (2)

- Store and Forward (2)

- System Integrators (2)

- Building Automation (1)

- ERP (1)

- Industrial AI (1)

- LGH User Stories (1)

- LRC (1)

- Linux (1)

- Machine Learning (1)

- Mining/Metals (1)

- New Release (1)

- Omni Flow (1)

- Power & Utilities (1)

- Predictive Analytics (1)

- Process Alerts (1)

- QNX (1)

- Sparkplug B (1)

- Water & Wastewater (1)