If you've been following along with our latest blog posts, you've probably heard Kepware Edge mentioned alongside the newly released version 7 of TOP Server. The question you may have now is: where does this fit, and how does it apply to me? The goal of this post is to answer this with a brief description and practical overview of Kepware Edge plus some case studies of when it makes sense to use it further below.

Software Toolbox Technical Blog

Recent Posts

Kepware Edge for Linux: What It Is & Where It Fits

5 min read

By Ryan Royse on Jan 22, 2026 2:29:59 PM

TOP Server V7 Has Arrived – So What’s New?

4 min read

By Ryan Royse on Dec 4, 2025 2:00:00 PM

By now, you’ve probably heard that TOP Server V7 has officially landed. Maybe you’ve seen the announcements or caught a quick overview along the way. But if you find yourself wondering, “Okay, but what does this release actually change for me?” you’re in the right place.

While V7 continues to reinforce the stability and reliability TOP Server is known for, this release also introduces several important enhancements aimed at strengthening enterprise deployments, simplifying user management, and modernizing system compatibility. Whether you’re operating on the latest infrastructure or maintaining long-standing environments, V7 delivers meaningful improvements that make deployment more flexible, secure, and future-ready.

Let’s take a closer look at what’s new.

How TOP Server Helps You Avoid Manufacturing Nightmares

6 min read

By Ryan Royse on Oct 30, 2025 4:45:00 PM

While Halloween and this time of year offers a few good scares, our customers in manufacturing face year-round nightmares that are far less fun: connectivity issues that stop production and unreliable data collection that restricts their ability to make informed decisions.

When your SCADA system can't communicate with your PLCs, your MES is missing critical data, and your operators are working without visibility into what's actually happening on the production floor, you're dealing with the kind of problems that lead to unplanned downtime, missed targets, and lost productivity.

In this post, we'll run through how our TOP Server handles common connectivity challenges, cover some practical tips for getting the most out of your setup, and show you how using remote configuration tools can simplify management across multiple servers, which all enable you to focus on production instead of troubleshooting communication nightmares.

UNS Without the Overhaul: Modernizing Industrial Data with Software Toolbox

4 min read

By Ryan Royse on Jul 17, 2025 2:00:00 PM

Welcome to the launch of Software Toolbox’s Summer of IoT blog series for 2025.

In the coming posts, we’ll explore how our solutions support the evolving world of the Industrial Internet of Things (IIoT), and more importantly, how they can help you advance your Industry 4.0 and digital transformation goals with practical, proven tools. We begin the series by exploring Unified Namespace (UNS), what it means, why it matters, and how Software Toolbox makes it practical for real-world industrial environments.

Unified Namespace, Real Results: Lessons and Tools that Deliver

In today’s fast-evolving industrial landscape, seamless connectivity and data integration are critical for operational success. At Software Toolbox, our solutions are designed to empower businesses by enabling UNS connectivity, bridging the gap between diverse systems and helping with efficiency, interoperability, and scalability.

Personally, as a presenter and attendee of ProveIt! 2025 and an attendee of 4.0 Solutions’ Edge Integration to UNS Workshop, I have had a lot of exposure to the topic of UNS this year. In this blog post, I will share not only what I have learned surrounding the topic, but how Software Toolbox’s solutions fit into the picture.

Demystifying Modbus Function Codes

6 min read

By Ryan Royse on Jan 9, 2025 2:00:00 PM

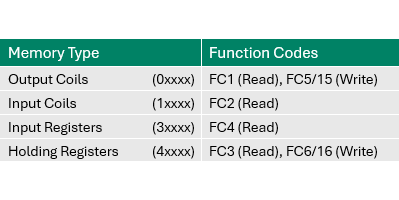

When working with Modbus communication, understanding the key concept of function codes is essential for ensuring efficient and accurate data exchange. Sometimes a device manual might only refer to the supported Modbus function codes and the range of offsets available for those function codes. A solid understanding of function codes is critical in achieving optimized performance and resolving potential communication issues.

After reading this blog, you'll know how you can leverage TOP Server’s Modbus driver to automatically handle the appropriate function codes for your application – while also taking advantage of its flexibility and other advanced features – to enhance performance, ensure compatibility with your devices, and reduce troubleshooting time.

Modbus Block Sizes for Faster, Smarter Data Collection

10 min read

By Ryan Royse on Nov 7, 2024 2:00:00 PM

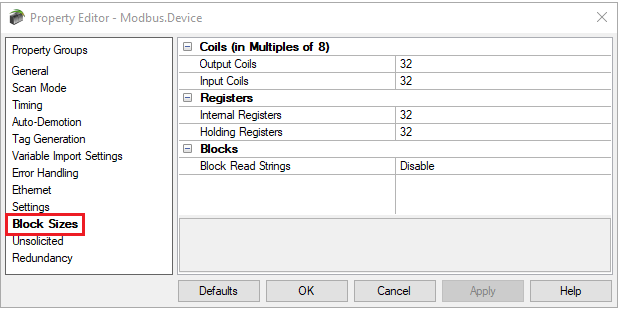

When working with Modbus devices and TOP Server, one critical factor that can significantly influence communication efficiency is the concept of block sizes. Optimizing block sizes for your application ensures smooth data transfer between your Modbus device and TOP Server, improving overall system performance.

In this blog, we’ll talk about what Modbus block sizes are, why they matter, and how to configure them effectively in TOP Server for the best results. We’ll also cover what happens when a block request includes non-contiguous addresses or undefined memory, causing potential issues with valid data. Additionally, it is important to note that other drivers/protocols may utilize block sizes as well, so these concepts could apply to other protocols beyond just Modbus.

Data Storage Deep Dive: Your Intro to Unlocking Historical Data

8 min read

By Ryan Royse on Sep 12, 2024 2:00:00 PM

Welcome to the kickoff post of our Data Storage Deep Dive blog series! In this series, we will explore the crucial role of data storage solutions and Historians in industrial automation. Over the coming weeks, we’ll be looking into how solutions delivered by Software Toolbox can be utilized with Historians, helping you make the most of your industrial data.

IoT and You – Kicking off the Summer of IoT

8 min read

By Ryan Royse on Jun 6, 2024 2:00:00 PM

Welcome to the kickoff of Software Toolbox’s Summer of IoT blog series! Over the next few blog posts, we’ll discuss how our products can play a role in the exciting world of Internet of Things (IoT), but more importantly, how they can be used to further your success in Industry 4.0 and Digital Transformation initiatives. The IoT landscape has grown exponentially over the past decade, transforming industries by connecting devices, systems, and people in unprecedented ways. IoT is reshaping how we interact with technology. At Software Toolbox, we recognize the power of IoT and are committed to providing solutions that facilitate this technological revolution.

About this Blog

We're engineers like you, so this blog focuses on "How to" appnotes, videos, tech team tips, product update announcements, user case studies, and other technical updates. Subscribe to updates below. Your feedback and questions on posts are always welcomed.

Subscribe to our Blog

Recent Posts

Posts by Topic

- Device Connectivity (205)

- Wonderware (178)

- OPC UA (121)

- Cogent DataHub (111)

- TOP Server (108)

- OPC (103)

- Technical Support (99)

- OmniServer (73)

- Video Tutorials (69)

- OPC Router (52)

- OPC DA (42)

- Protocols (40)

- AVEVA (37)

- Automation 101 (28)

- Security (26)

- MQTT & IoT (24)

- OmniServer Did You Know (24)

- Data Tunneling (23)

- Connectivity (22)

- OPC Data Client (22)

- Development Tools (19)

- IT/OT (19)

- DCOM (17)

- LGH (14)

- OPC Tunnel (13)

- Alarms & Notifications (12)

- Database (12)

- Earth Day (12)

- Summer of IoT (12)

- Exploring OPC UA (11)

- OPC Gateway (11)

- REST & Web Services (11)

- Case Studies (10)

- Dream Report (10)

- EFM (10)

- Oil & Gas (10)

- Reporting (10)

- CSV (9)

- Database & Historian (9)

- OPC Integration (9)

- Flow (8)

- OPC Server (8)

- Redundancy (8)

- Sustainability (8)

- AVEVA OPC UA Client (7)

- Modbus (7)

- OPC Router Basic Training (7)

- SuiteLink (7)

- DataHub Training (6)

- ODBC (6)

- OPC Alarms and Events (6)

- OPC Conversion (6)

- OPC Data Logger (6)

- ProtocolDesign (6)

- xml (6)

- Data Bridging (5)

- Data Logging (5)

- Data Storage Deep Dive (5)

- Business Intelligence (4)

- Data Integration (4)

- InTouch (4)

- Industrial Decisions (4)

- Industry 4.0 (4)

- OPC Bridge (4)

- OPC Redundancy (4)

- OPC Toolkit Benefits (4)

- OmniServer User Stories (4)

- SLIK-DA (4)

- SQL (4)

- Collaboration (3)

- Error Detection (3)

- IT & Infrastructure (3)

- OPC Server Remote Config (3)

- Wedges (3)

- Windows (3)

- ControlLogix (2)

- Excel (2)

- Ignition (2)

- KEPServerEX (2)

- Kepware Edge (2)

- OPC Wizard (2)

- OSIsoft (2)

- Omron (2)

- PGAS (2)

- Predictive Maintenance (2)

- Process Alert (2)

- Scripting (2)

- Store and Forward (2)

- System Integrators (2)

- Building Automation (1)

- ERP (1)

- Industrial AI (1)

- LGH User Stories (1)

- LRC (1)

- Linux (1)

- Machine Learning (1)

- Mining/Metals (1)

- New Release (1)

- Omni Flow (1)

- Power & Utilities (1)

- Predictive Analytics (1)

- Process Alerts (1)

- QNX (1)

- Sparkplug B (1)

- Water & Wastewater (1)