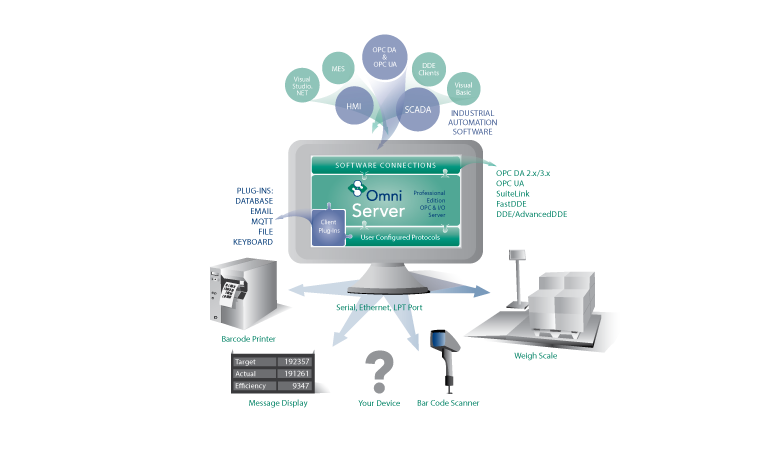

OmniServer is a universal data acquisition application designed to bi-directionally exchange data with a wide range of Ethernet, serial, or USB devices that use “non-standard protocols” such as weigh scales, barcode readers, lab instruments, inspection machines, printers, and more.

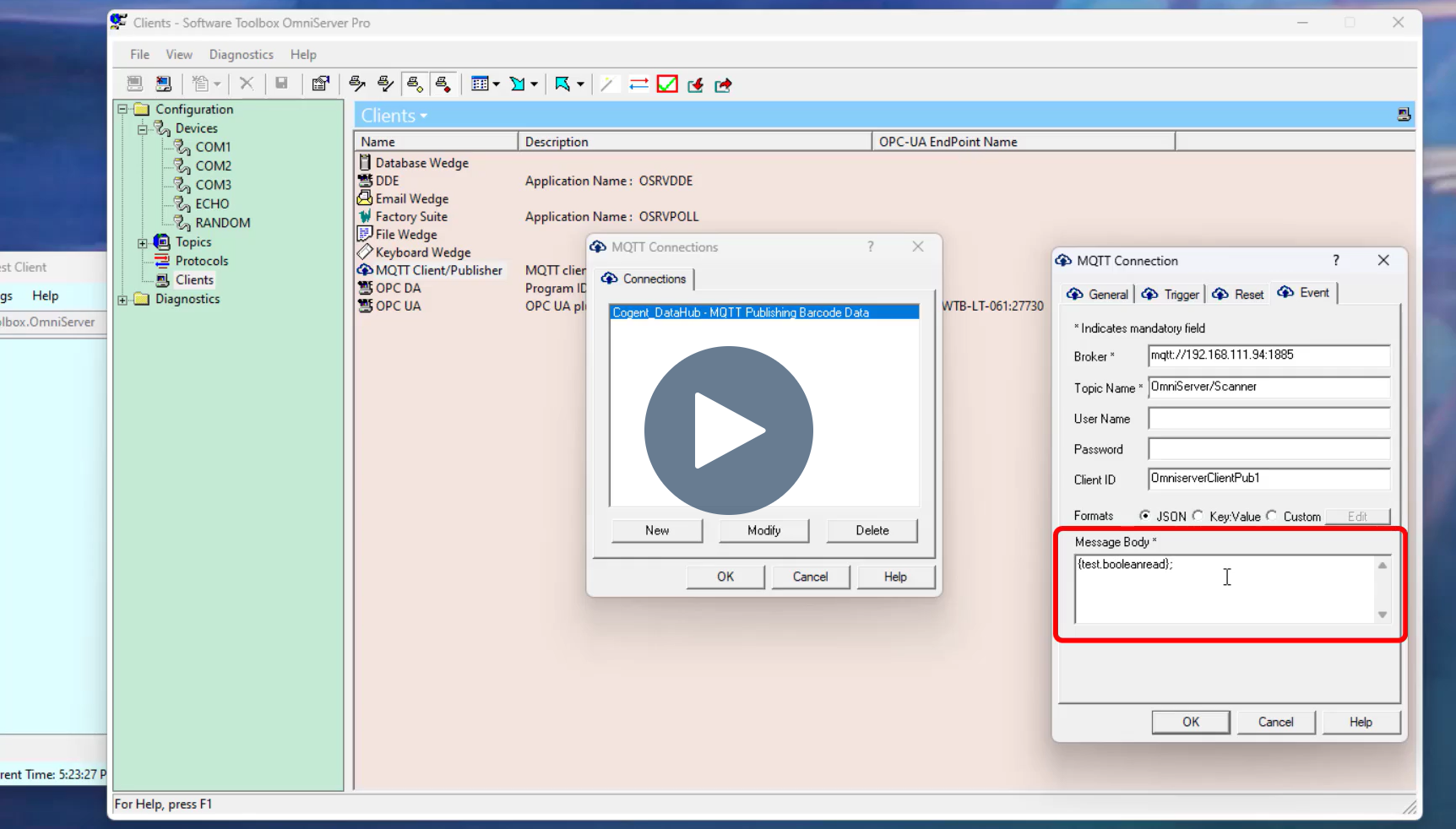

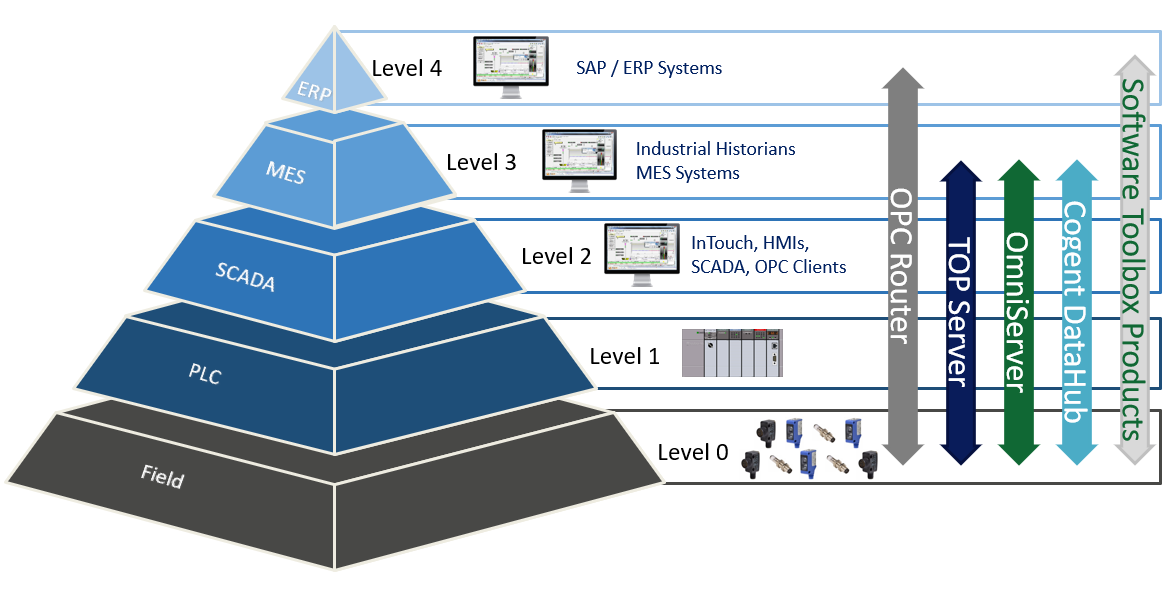

The wide range of connectivity options enable OmniServer to send that data to HMI, SCADA, MES, or Historian systems using standard interfaces like OPC DA, OPC UA, and AVEVA SuiteLink. It also has an optional MQTT Client Plug-In that allows users to publish data to MQTT Brokers.