In the oil and gas industry, data drives everything—from production optimization to regulatory compliance and remote asset management. But in an environment with geographically dispersed assets, legacy equipment, and too often limited network bandwidth, secure data exchange is far from simple.

To stay competitive and compliant, oil and gas operators must bridge the gap between edge devices to control and enterprise systems—safely, reliably, and in real time.

Software Toolbox Technical Blog

Securing Oil and Gas Data Exchange with Software Toolbox Solutions

6 min read

By Jay David on May 1, 2025 2:00:00 PM

Harnessing Waste Heat for a Greener Future

5 min read

By Zachary Parham on Apr 10, 2025 2:00:00 PM

When it comes to Earth Day, conversations often center on renewable energy and reducing raw materials—but true sustainability goes far beyond solar panels and recycling bins. One of the most overlooked yet powerful ways to shrink our environmental footprint is by reclaiming something we already have in abundance: waste heat.

In this second installment of our 2025 Environmental Sustainability blog series, we’re diving into the surprisingly diverse world of heat reclamation—where compost piles, underground aquifers, industrial processes, and even your HVAC system can all become unexpected sources of clean, efficient energy.

Curious about how this is so? Read on to discover the technologies that turn excess heat into big savings—for both the planet and your wallet.

Standardizing Connectivity to Advance Sustainability

6 min read

By Jay David on Apr 3, 2025 2:00:00 PM

How a Common Data Infrastructure is Helping Amcor Meet its Net Zero Goals

We are celebrating World Earth Day all month long and recognize that sustainability is not just about using eco-friendly materials — it is about making smarter choices in how we connect, operate, optimize, and innovate. To kick things off, this first blog of this year's Earth Day Series explores how Amcor, a global leader in the packaging industry, is leveraging TOP Server to drive efficiency, improve productivity, and help support its sustainability goals.

From Plant Floor PLC to SAP: Real-Time Connectivity

5 min read

By Kyle Persyn on Feb 20, 2025 2:00:00 PM

A global beverage manufacturer sought to modernize its data workflows by integrating operational technology (OT) with enterprise systems. Specifically, they needed to transfer real-time data from their Rockwell Automation PLCs to their SAP system to automate workflows, enhance traceability, and streamline processes. The legacy setup relied on outdated communication methods, introducing inefficiencies and potential failure points. To overcome these challenges, the company required a robust, scalable, and future-ready solution.

This blog will give you an insight into how that solution became a reality and how they got there. Also, if you have not done so, please subscribe to our blogs to not miss out on similar topics.

Unlock Oil and Gas Operational Excellence - Software Toolbox Solutions

6 min read

By Seann Gallagher on Jan 30, 2025 2:00:00 PM

Streamline Operations, Improve Visibility, Enable Compliance, and Drive Success

In the highly regulated and fast-paced oil and gas industry, leveraging real-time, secure data is crucial for improving operational efficiency, ensuring safety, and meeting regulatory compliance standards. Software Toolbox delivers software solutions designed to enable data integration that is a must for the applications you use to monitor, manage, streamline and optimize operations across all sectors of the oil and gas value chain. Our solutions deliver the critical data you need, whether you're in upstream exploration, midstream pipeline management, or downstream refining.

Read the rest of the blog to learn how we can help drive your operations forward.

Demystifying Modbus Function Codes

6 min read

By Ryan Royse on Jan 9, 2025 2:00:00 PM

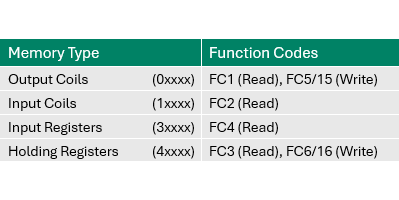

When working with Modbus communication, understanding the key concept of function codes is essential for ensuring efficient and accurate data exchange. Sometimes a device manual might only refer to the supported Modbus function codes and the range of offsets available for those function codes. A solid understanding of function codes is critical in achieving optimized performance and resolving potential communication issues.

After reading this blog, you'll know how you can leverage TOP Server’s Modbus driver to automatically handle the appropriate function codes for your application – while also taking advantage of its flexibility and other advanced features – to enhance performance, ensure compatibility with your devices, and reduce troubleshooting time.

Prepared for DNP3 EFM Export from the Emerson FB Automation Platform?

5 min read

By Zachary Parham on Dec 12, 2024 2:00:00 PM

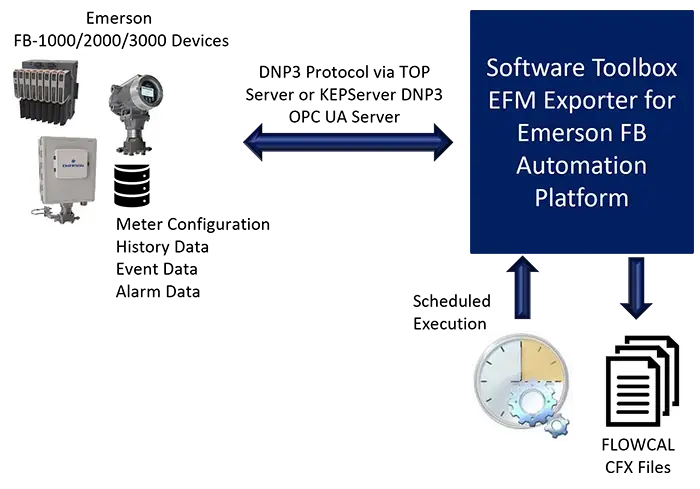

When you hear "EFM data", you probably think of well-known Oil & Gas devices like ABB TotalFlow, Fisher ROC, or OMNI Flow and their native protocols, or perhaps Enron Modbus. However, the Oil & Gas industry is quickly embracing the DNP3 protocol for its speed and security in pipeline monitoring.

Current generation Emerson devices, like the FB1000 and FB2000 Series Flow Computers or FB3000 RTUs, support secure DNP3, which is the recommended protocol by Emerson. But how can you extract both real-time data as well as EFM alarm, event and flow history data from them? Don’t worry, we’ve got you covered!

In this blog, you’ll learn about the powerful capabilities of the DNP3 protocol and how you can use the TOP Server DNP3 Driver and Software Toolbox EFM Exporter for Emerson FB Automation Platform together to efficiently and accurately provide automated, scheduled liquid and gas real-time and accounting data retrieval from your Emerson Devices and export that EFM data to the FLOWCAL CFX format.

Modbus Block Sizes for Faster, Smarter Data Collection

10 min read

By Ryan Royse on Nov 7, 2024 2:00:00 PM

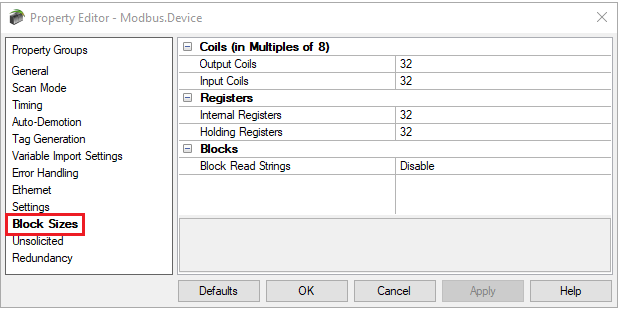

When working with Modbus devices and TOP Server, one critical factor that can significantly influence communication efficiency is the concept of block sizes. Optimizing block sizes for your application ensures smooth data transfer between your Modbus device and TOP Server, improving overall system performance.

In this blog, we’ll talk about what Modbus block sizes are, why they matter, and how to configure them effectively in TOP Server for the best results. We’ll also cover what happens when a block request includes non-contiguous addresses or undefined memory, causing potential issues with valid data. Additionally, it is important to note that other drivers/protocols may utilize block sizes as well, so these concepts could apply to other protocols beyond just Modbus.

About this Blog

We're engineers like you, so this blog focuses on "How to" appnotes, videos, tech team tips, product update announcements, user case studies, and other technical updates. Subscribe to updates below. Your feedback and questions on posts are always welcomed.

Subscribe to our Blog

Recent Posts

Posts by Topic

- Device Connectivity (205)

- Wonderware (178)

- OPC UA (121)

- Cogent DataHub (111)

- TOP Server (108)

- OPC (103)

- Technical Support (99)

- OmniServer (73)

- Video Tutorials (69)

- OPC Router (52)

- OPC DA (42)

- Protocols (40)

- AVEVA (37)

- Automation 101 (28)

- Security (26)

- MQTT & IoT (24)

- OmniServer Did You Know (24)

- Data Tunneling (23)

- Connectivity (22)

- OPC Data Client (22)

- Development Tools (19)

- IT/OT (19)

- DCOM (17)

- LGH (14)

- OPC Tunnel (13)

- Alarms & Notifications (12)

- Database (12)

- Earth Day (12)

- Summer of IoT (12)

- Exploring OPC UA (11)

- OPC Gateway (11)

- REST & Web Services (11)

- Case Studies (10)

- Dream Report (10)

- EFM (10)

- Oil & Gas (10)

- Reporting (10)

- CSV (9)

- Database & Historian (9)

- OPC Integration (9)

- Flow (8)

- OPC Server (8)

- Redundancy (8)

- Sustainability (8)

- AVEVA OPC UA Client (7)

- Modbus (7)

- OPC Router Basic Training (7)

- SuiteLink (7)

- DataHub Training (6)

- ODBC (6)

- OPC Alarms and Events (6)

- OPC Conversion (6)

- OPC Data Logger (6)

- ProtocolDesign (6)

- xml (6)

- Data Bridging (5)

- Data Logging (5)

- Data Storage Deep Dive (5)

- Business Intelligence (4)

- Data Integration (4)

- InTouch (4)

- Industrial Decisions (4)

- Industry 4.0 (4)

- OPC Bridge (4)

- OPC Redundancy (4)

- OPC Toolkit Benefits (4)

- OmniServer User Stories (4)

- SLIK-DA (4)

- SQL (4)

- Collaboration (3)

- Error Detection (3)

- IT & Infrastructure (3)

- OPC Server Remote Config (3)

- Wedges (3)

- Windows (3)

- ControlLogix (2)

- Excel (2)

- Ignition (2)

- KEPServerEX (2)

- Kepware Edge (2)

- OPC Wizard (2)

- OSIsoft (2)

- Omron (2)

- PGAS (2)

- Predictive Maintenance (2)

- Process Alert (2)

- Scripting (2)

- Store and Forward (2)

- System Integrators (2)

- Building Automation (1)

- ERP (1)

- Industrial AI (1)

- LGH User Stories (1)

- LRC (1)

- Linux (1)

- Machine Learning (1)

- Mining/Metals (1)

- New Release (1)

- Omni Flow (1)

- Power & Utilities (1)

- Predictive Analytics (1)

- Process Alerts (1)

- QNX (1)

- Sparkplug B (1)

- Water & Wastewater (1)